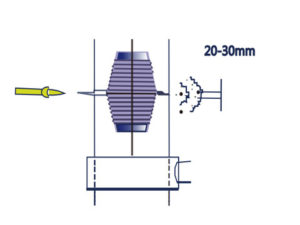

Graphite electrode nipple is an accessory for the graphite electrode and is used in conjunction with graphite electrode. A graphite nipple projecting from one end of a graphite electrode portion of the type used in an electric furnace has a supporting face for receiving a non-graphite portion of a clamping device in shape-locking engagement for holding the electrode for use. It also has a conventional screw-thread surface for joining the nipple to another electrode portion for extending the electrode. Graphite eletrode nipple is used for assembling and supporting electrode portions in an electric furnace, which is essential in the use of graphite electrode. If you want to buy high quality graphite electrode nipple, Contact us for free price list!

Graphite Electrode Nipple Features

- Rugged construction

- Anti-corrosive

- Easy to install

Graphite Electrode Nipple Specification

| Properties | Units of measurement | Typical values | |||

| Diameter | mm | 75-150 | 200-350 | 400-550 | 600-700 |

| Bulk density | g/cm3 | 1.68 | 1.77 | 1.80 | 1.82 |

| Ash impurities | % | 0.2 | 0.2 | 0.2 | 0.2 |

| Specific electrical resistance | µОhm•m | 5.5 | 4.5 | 4.2 | 4.0 |

| Linear thermal expansion coefficient, (20-520)ºС | 10-6 •1/°С | 2.2 | 1.1 | 1.2 | 1.1 |

| Flexural strength | MPa | 16 | 17 | 22 | 23 |

| Modulus of elasticity (Young’s modulus) | GPa | – | 17 | 17 | 18 |

Note: the above values are average values and they do not constitute a specification

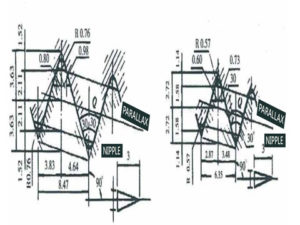

Detailer Parameter of 4TPI NIPPLE

| DIMENSIONS OF TRUNCATED NIPPLES(4TPI) | |||||||||||||

| Diameter | Nipple | Electrode socket | Pitch | ||||||||||

| mm | inch | D | L | d2 | l | d1 | H | ||||||

| 300 | 12 | 177.80 | -0.5-0 | 215.90 | -1-0 | 129.20 | -5-0 | <7 | 171.48 | 0-+0.5 | 114.00 | 0-+7 | 6.35 |

| 350 | 14 | 203.20 | -0.5-0 | 254.00 | -1-0 | 148.20 | -5-0 | <7 | 196.88 | 0-+0.5 | 133.00 | 0-+7 | 6.35 |

| 400 | 16 | 222.25 | -0.5-0 | 304.80 | -1-0 | 158.80 | -5-0 | <7 | 215.93 | 0-+0.5 | 158.40 | 0-+7 | 6.35 |

| 400 | 16 | 222.25 | -0.5-0 | 355.60 | -1-0 | 150.00 | -5-0 | <7 | 215.93 | 0-+0.5 | 183.80 | 0-+7 | 6.35 |

| 450 | 18 | 241.30 | -0.5-0 | 304.80 | -1-0 | 177.90 | -5-0 | <7 | 234.98 | 0-+0.5 | 158.40 | 0-+7 | 6.35 |

| 450 | 18 | 241.30 | -0.5-0 | 355.60 | -1-0 | 169.42 | -5-0 | <7 | 234.98 | 0-+0.5 | 183.80 | 0-+7 | 6.35 |

| 500 | 20 | 269.88 | -0.5-0 | 355.60 | -1-0 | 198.00 | -5-0 | <7 | 263.56 | 0-+0.5 | 183.80 | 0-+7 | 6.35 |

| 500 | 20 | 269.88 | -0.5-0 | 181.08 | -1-0 | 181.08 | -5-0 | <7 | 263.56 | 0-+0.5 | 234.60 | 0-+7 | 6.35 |

| 550 | 22 | 298.45 | -0.5-0 | 226.58 | -1-0 | 226.58 | -5-0 | <7 | 292.13 | 0-+0.5 | 183.80 | 0-+7 | 6.35 |

| 550 | 22 | 298.45 | -0.5-0 | 209.65 | -1-0 | 209.65 | -5-0 | <7 | 292.13 | 0-+0.5 | 234.60 | 0-+7 | 6.35 |

| 600 | 24 | 317.5 | -0.5-0 | 245.63 | -1-0 | 245.63 | -5-0 | <7 | 311.18 | 0-+0.5 | 183.80 | 0-+7 | 6.35 |

| 600 | 24 | 317.5 | -0.5-0 | 228.70 | -1-0 | 228.70 | -5-0 | <7 | 311.18 | 0-+0.5 | 234.60 | 0-+7 | 6.35 |

Sizes of graphite nipples and electrode sockets with Т4 taper thread

| Nominal Electrode Diameter | Joint Designation | Nipple | Electrode Socket | ||||

| External Diameter | Effective Diameter | Length | External Diameter | Depth | Thread depth | ||

| d1 | d2 | L1 | d4 | L2 | L3 | ||

| 200 | 122Т4N | 122.24 | 119.08 | 177.80 | 119.08 | 94.90 | 90.90 |

| 225 | 139Т4N | 139.70 | 136.54 | 177.80 | 136.54 | 94.90 | 90.90 |

| 250 | 152Т4N | 152.40 | 149.24 | 190.50 | 149.24 | 101.30 | 97.30 |

| 300 | 177Т4N | 177.80 | 174.64 | 215.90 | 174.64 | 114.00 | 110.00 |

| 350 | 203Т4N | 203.20 | 200.04 | 254.00 | 200.04 | 133.00 | 129.00 |

| 350 | 203Т4L | 203.20 | 200.04 | 304.80 | 200.04 | 158.40 | 154.40 |

| 400 | 222Т4N | 222.25 | 219.09 | 304.80 | 219.09 | 158.40 | 154.40 |

| 400 | 222Т4L | 222.25 | 219.09 | 355.60 | 219.09 | 183.80 | 179.80 |

| 450 | 241Т4N | 241.30 | 238.14 | 304.80 | 238.14 | 158.40 | 154.40 |

| 450 | 241Т4L | 241.30 | 238.14 | 355.60 | 238.14 | 183.80 | 179.80 |

| 500 | 269Т4N | 269.88 | 266.72 | 355.60 | 266.72 | 183.80 | 179.80 |

| 500 | 269Т4L | 269.88 | 266.72 | 457.20 | 266.72 | 234.60 | 230.60 |

| 550 | 298Т4N | 298.45 | 295.29 | 355.60 | 295.29 | 183.80 | 179.80 |

| 550 | 298Т4L | 298.45 | 295.29 | 457.20 | 295.29 | 234.60 | 230.60 |

| 600 | 317Т4N | 317.50 | 314.34 | 355.60 | 314.34 | 183.80 | 179.80 |

| 600 | 317Т4L | 317.50 | 314.34 | 457.20 | 314.34 | 234.60 | 230.60 |

| 650 | 355Т4N | 355.60 | 352.44 | 457.20 | 352.44 | 234.60 | 230.60 |

| 650 | 355Т4L | 355.60 | 352.44 | 558.80 | 352.44 | 285.40 | 281.40 |

| 700 | 317Т4L | 317.50 | 314.34 | 457.20 | 314.34 | 234.60 | 230.60 |

| 700 | 374Т4N | 374.65 | 371.49 | 457.20 | 371.49 | 234.60 | 230.60 |

| 700 | 374Т4L | 374.65 | 371.49 | 558.80 | 371.49 | 285.40 | 281.40 |

Note: Nipple effective diameter d2 is equal to electrode socket effective diameter d4

Other combinations of the nominal diameter and the joint are to be agreed upon with a consumer

Detailer parameter of 3TPI NIPPLE

| DIMENSIONS OF TRUNCATED NIPPLES (3TPI) | |||||||||||||

| Diameter | Nipple | Electrode Socket | Pitch | ||||||||||

| mm | inch | D | L | d2 | l | d1 | H | ||||||

| 300 | 12 | 177.16 | -0.5-0 | 270.9 | -1-0 | 116.9 | -5-0 | <10 | 168.73 | 0-+0.5 | 141.5 | 0-+7 | 8.47 |

| 350 | 14 | 215.9 | -0.5-0 | 304.8 | -1-0 | 150.0 | -5-0 | <10 | 207.47 | 0-+0.5 | 158.4 | 0-+7 | 8.47 |

| 400 | 16 | 215.9 | -0.5-0 | 304.8 | -1-0 | 150.0 | -5-0 | <10 | 207.47 | 0-+0.5 | 158.4 | 0-+7 | 8.47 |

| 400 | 16 | 241.3 | -0.5-0 | 338.7 | -1-0 | 169.8 | -5-0 | <10 | 232.87 | 0-+0.5 | 175.3 | 0-+7 | 8.47 |

| 450 | 18 | 241.3 | -0.5-0 | 338.7 | -1-0 | 169.8 | -5-0 | <10 | 232.87 | 0-+0.5 | 175.3 | 0-+7 | 8.47 |

| 450 | 18 | 273.05 | -0.5-0 | 355.6 | -1-0 | 198.7 | -5-0 | <10 | 264.62 | 0-+0.5 | 183.8 | 0-+7 | 8.47 |

| 500 | 20 | 273.05 | -0.5-0 | 355.6 | -1-0 | 198.7 | -5-0 | <10 | 264.62 | 0-+0.5 | 183.8 | 0-+7 | 8.47 |

| 500 | 20 | 298.45 | -0.5-0 | 372.6 | -1-0 | 221.3 | -5-0 | <10 | 290.02 | 0-+0.5 | 192.2 | 0-+7 | 8.47 |

| 550 | 22 | 298.45 | -0.5-0 | 372.6 | -1-0 | 221.3 | -5-0 | <10 | 290.02 | 0-+0.5 | 192.2 | 0-+7 | 8.47 |

Sizes of graphite nipples and electrode sockets with Т3 taper thread

| Nominal Electrode Diameter | Joint Designation | Nipple | Electrode Socket | ||||

| External Diameter | Effective Diameter | Length | Effective Diameter | Depth | Thread depth | ||

| 225 | 139Т3N | 139.70 | 135.49 | 203.20 | 135.49 | 107.60 | 103.60 |

| 250 | 155Т3N | 155.57 | 151.36 | 220.00 | 151.36 | 116.00 | 112.00 |

| 300 | 177Т3N | 177.16 | 172.95 | 270.90 | 172.95 | 141.50 | 137.50 |

| 350/400 | 215Т3N | 215.90 | 211.69 | 304.80 | 211.69 | 158.40 | 154.40 |

| 350/400 | 215Т3L | 215.90 | 211.69 | 355.60 | 211.69 | 183.80 | 179.80 |

| 400/450 | 241Т3N | 241.30 | 237.09 | 338.70 | 237.09 | 175.30 | 171.30 |

| 400/450 | 241Т3L | 241.30 | 237.09 | 355.60 | 237.09 | 183.80 | 179.80 |

| 500 | 273Т3N | 273.05 | 268.84 | 355.60 | 268.84 | 183.80 | 179.80 |

| 500 | 273Т3L | 273.05 | 268.84 | 457.20 | 268.84 | 234.60 | 230.60 |

| 550 | 298Т3L | 298.45 | 294.24 | 457.20 | 294.23 | 234.60 | 230.60 |

Note: Nipple effective diameter d2 is equal to electrode socket effective diameter d3

Sizes of graphite nipples and electrode sockets with cylindrical thread 3 turns per inch (C3)

| Nominal Electrode Diameter | Joint Designation | Nipple | Electrode Socket | ||

| Diameter

d |

Length

L |

External Diameter

d1 |

Socket depth

L1 |

||

| 75 | 41С3N | 41.2 | 103.0 | 35.1 | 53.0 |

| 100 | 66C3N | 66.7 | 135.0 | 60.6 | 69.0 |

| 125 | 69C3N | 69.8 | 153.0 | 63.7 | 78.0 |

| 150 | 88C3N | 88.9 | 169.0 | 82.8 | 86.0 |

| 200 | 122C3N | 122.2 | 203.0 | 116.1 | 103.0 |

Note: Nipples from 75 mm to 200 mm in diameter are made without holes for plugs.

Date of conical electrode nipples

NOTE:The technical index of the connector is shown in the technical index of the supporting electrode.

Graphite Electrode Nipple Production cautions

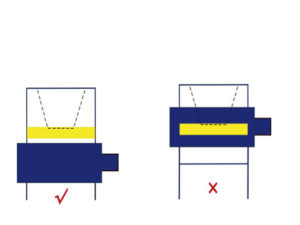

It is necessary to clean out the dirt in the socket with compressed air when a new electrode is connected to the nipple.

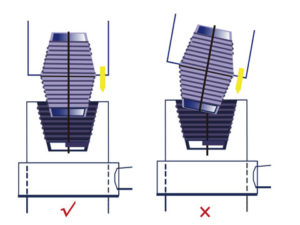

When connecting, the electrode should be aligned with the center axis of the nipple.

The electrode clamp holder should be placed outside of the two security lines where the nipple is to be positioned.

Before screwing the electrode, the dust on the surface of the electrode should be blown out with compressed air.

Graphite Electrode Nipple Manufacturers

RS Kiln Refractory Company is a top professional manufacturer & supplier of graphite electrodes in China, in the last decade our products were exported to more than 30 foreign countries and areas and got high reputation from our customers all over the world. We constantly invest in our production technologies and in international advanced key equipments in order that the quality of graphite electrodes products produced in RS is up to international advanced level. We have established our own professional technical & after-sales service teams and provide our clients with timely and excellent service. We commit ourselves to assisting the clients to reduce production cost and increase productivity. In short, RS must be a reliable refractory manufacturer, we won’t let you down if you choose to cooperate with us. Just Email us for getting what you want!