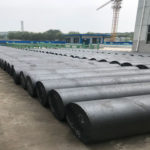

Understanding Graphite Electrodes and Their Industrial Uses. In every modern foundry, steel plant, or metallurgical operation, graphite electrodes play an irreplaceable role. They serve as the crucial conductors that transform electrical energy into the intense heat needed to melt metal, refine alloys, or process high-temperature materials.

But graphite electrodes uses extend far beyond just melting steel. From silicon production to chemical engineering and energy storage, these carbon-based tools form the backbone of high-temperature industries.

Rongsheng, a professional graphite electrode manufacturer and supplier, offers a complete range of electrode products — including discount RP graphite electrodes — designed to deliver durability, conductivity, and affordability for customers worldwide.

What Are Graphite Electrodes?

Graphite electrodes are cylindrical carbon products made from high-quality raw materials such as needle coke, petroleum coke, and coal pitch. These materials undergo mixing, forming, baking, impregnation, and graphitization at temperatures up to 3000°C, resulting in electrodes that are lightweight, electrically conductive, and thermally stable.

The purpose of a graphite electrode is to conduct large electrical currents into a furnace, generating arcs hot enough to melt scrap metal or raw materials. Because of their unique structure and high melting point, graphite electrodes maintain stability under intense electrical, chemical, and mechanical conditions.

Rongsheng’s production process ensures that every electrode meets strict international standards — balancing high mechanical strength, low resistivity, and minimal consumption rates.

Graphite Electrodes Uses in Modern Industry

While steelmaking remains the main field of application, the uses of graphite electrodes have diversified in recent years due to technological advances and new material demands.

1. Steelmaking in Electric Arc Furnaces (EAFs)

The most prominent use of graphite electrodes is in EAF steelmaking, where electrodes form arcs between their tips and the scrap steel charge.

-

The arcs reach temperatures above 3000°C, melting metal efficiently.

-

Rongsheng’s RP (Regular Power) graphite electrodes are ideal for smaller or mid-capacity furnaces operating under standard current loads.

-

For high-output operations, HP and UHP electrodes deliver faster melting and longer service life.

Graphite electrodes’ low resistivity allows for optimal energy conversion, reducing electricity costs and improving furnace productivity.

2. Secondary Refining in Ladle Furnaces (LFs)

Graphite electrodes also serve in ladle furnaces, maintaining molten steel at precise temperatures for refining or alloy adjustments.

-

Rongsheng’s electrodes ensure stable current flow and consistent heating performance.

-

This application requires strong oxidation resistance and dimensional accuracy to maintain long service intervals.

3. Ferroalloy and Non-Ferrous Metal Production

In submerged arc furnaces used to produce ferroalloys, silicon, or yellow phosphorus, electrodes are inserted directly into the furnace charge.

-

They must withstand both arc and resistance heating.

-

Rongsheng’s RP graphite electrodes, particularly available in discount form, offer stable performance in these cost-sensitive operations.

4. Chemical and Refractory Industries

Graphite electrodes also act as heating sources for producing corundum, silicon carbide, and high-purity quartz products.

-

The stability and high heat conductivity of graphite ensure continuous and uniform heating during long production cycles.

5. Emerging Energy and Industrial Applications

Beyond traditional furnaces, graphite electrodes are being explored in:

-

Battery and energy storage technologies as conductive additives.

-

Carbon arc gouging for precision welding and metal removal.

-

Graphitization furnaces for advanced carbon materials manufacturing.

These applications showcase the versatility of graphite as both a structural and conductive material across industries.

Rongsheng’s Discount RP Graphite Electrodes – Cost-Effective Quality

Among its product lineup, Rongsheng’s discount RP graphite electrodes have become one of the most popular choices for small to mid-sized industrial users. “RP” stands for Regular Power — electrodes designed for moderate current density and general-purpose furnace use.

Advantages of Rongsheng’s Discount RP Graphite Electrodes:

-

Stable Performance: Consistent electrical conductivity for steady arc operation.

-

Durable Construction: High mechanical strength reduces breakage during electrode feeding.

-

Thermal Stability: Withstands repeated heating and cooling cycles without cracking.

-

Cost Efficiency: Offers reliable performance at a more economical price, ideal for budget-conscious operations.

Rongsheng’s pricing advantage stems from factory-direct supply, bulk production capacity, and efficient logistics systems that reduce overhead costs without sacrificing quality.

How Rongsheng Ensures Electrode Reliability

At the heart of Rongsheng’s reputation as a graphite electrode supplier is its advanced manufacturing process. Each electrode is produced in its modern factory using precision control systems and strict quality management protocols.

The production process includes:

-

Material Selection: High-purity needle coke and pitch binder for optimal structure.

-

Forming and Baking: Ensures uniform density and stable mechanical strength.

-

Impregnation: Enhances density and oxidation resistance for longer life.

-

Graphitization: Converts carbon to crystalline graphite for maximum conductivity.

-

Machining: Electrodes and nipples are CNC-machined for exact dimensions and seamless joint connections.

-

Testing: Each batch undergoes resistivity, density, and mechanical performance checks before packaging.

This attention to detail guarantees that even discount RP graphite electrodes from Rongsheng deliver consistent quality and reliability comparable to higher-priced competitors.

Customer Application Example – Reliable Results at Reduced Cost

A South American foundry specializing in steel casting switched to Rongsheng’s discount RP graphite electrodes to reduce expenses without compromising production stability. Over six months, the foundry reported:

-

12% lower electrode consumption per ton of metal melted.

-

Reduced downtime caused by electrode replacement.

-

Improved furnace stability with consistent arc performance.

These results demonstrated how affordable electrodes can still deliver professional-grade performance when manufactured by a trusted supplier like Rongsheng.

Why Choose Rongsheng for Graphite Electrodes

-

Factory-Direct Supply: Elimination of intermediaries ensures competitive pricing and flexible order quantities.

-

Wide Product Range: RP, HP, and UHP graphite electrodes for various furnace types.

-

Customization Options: Tailored diameters, lengths, and nipple types to fit specific customer requirements.

-

Global Experience: Clients in more than 120 countries rely on Rongsheng’s expertise.

-

Technical Support: Professional guidance on electrode use, installation, and furnace optimization.

Whether a customer is seeking discount RP graphite electrodes for smaller furnaces or high-grade UHP types for intensive steelmaking, Rongsheng ensures dependable performance and global service support.

Conclusion

From traditional steelmaking to advanced material processing, the uses of graphite electrodes are as diverse as they are essential. Their unmatched ability to conduct electricity, endure heat, and resist wear keeps them at the core of countless industrial processes.

Rongsheng, a trusted manufacturer with decades of experience, continues to deliver high-quality graphite electrodes that meet the needs of global industries — combining efficiency, reliability, and affordability. Its discount RP graphite electrodes embody the company’s mission: to make world-class electrode technology accessible to every furnace operator.

📩 Contact Rongsheng today for pricing and technical consultation.

🌐 Visit the website to learn more about available graphite electrodes and applications.