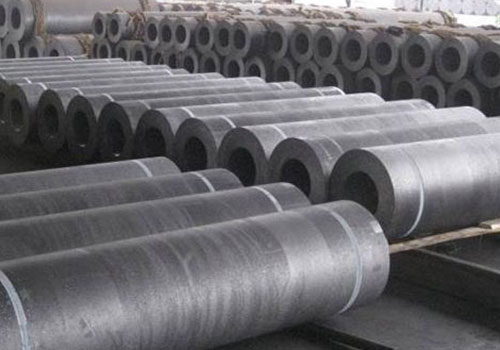

The graphite electrode is mainly made of petroleum coke and needle coke with coal pitch as the binder through calcination, batching, kneading, pressing, roasting, graphitization and machining. Electric arc furnace is used as conductive material. The quality of graphite electrode is excellent and can be bundled into composite electrode.

Ordinary power graphite electrode allows the use of graphite electrode whose current density is less than 17A/ cm 2. It is mainly used in ordinary power electric furnace for steelmaking, silicon smelting and yellow phosphorus smelting. High power graphite electrode allows the use of current density of 18~25A/ cm 2 graphite electrode, mainly used in steelmaking high power electric arc furnace. Ultra-high power graphite electrode allows the use of current density of more than 25A/ cm 2 graphite electrode, mainly used in ultra-high power steelmaking arc furnace.

The quality of graphite electrode can conduct current without melting. It has the advantages of fast processing speed, good machinability, light weight, good thermal stability, no deformation and no processing burr. Graphite electrode is widely used in the production of alloy steel, metal and other nonmetallic materials. The quality of graphite electrode determines the productivity and cost of eaf steelmaking.

Graphite electrodes joints are used to connect two or more electrodes in a column. The aim is to realize the continuous use of electrode in eaf steelmaking. The joint with the surface of traditional external thread is an important clamping device to extend the length of electrode. This can avoid non – productive consumption in smelting. High machining accuracy, good surface finish. Excellent resistance to breakage.

We are a professional Graphite electrode manufacturer, with rich production experience, excellent technical team. Graphite product quality and safety is guaranteed, the price is reasonable, welcome to consult and purchase.