Rongsheng’s Approach to Graphite Electrode Recovery and Furnace Efficiency. In modern steelmaking and metallurgy, efficiency and sustainability are no longer optional — they are essential. One key aspect of this efficiency lies in graphite electrode recovery, a process that helps reduce material waste, operational costs, and environmental impact.

As a professional graphite electrode manufacturer, Rongsheng has not only optimized electrode production but also developed strategies to help customers extend electrode life and recover value from used materials. Alongside this, Rongsheng continues to offer a wide range of arc furnace electrodes and graphite electrodes for sale, ensuring reliable performance across steel, alloy, and foundry applications.

Understanding Graphite Electrode Recovery

Graphite electrode recovery refers to the reuse, recycling, or repurposing of electrode materials that remain after furnace operations. During electric arc furnace (EAF) steelmaking, electrodes gradually wear down due to oxidation, sublimation, and mechanical stress. However, a significant portion of these used electrodes — often called “butts” — still retain structural and conductive integrity.

By processing and recovering this material, steel plants can:

-

Reduce Raw Material Costs: Recovered graphite can be used as a carbon additive or processed into new electrode components.

-

Minimize Waste: Recycling electrode remnants lowers landfill disposal and carbon emissions.

-

Improve Sustainability: Supports circular manufacturing and responsible use of carbon-based materials.

Rongsheng collaborates with steel mills worldwide to advise on electrode recovery practices, ensuring efficient material reuse without compromising quality or safety.

Arc Furnace Electrodes – The Backbone of Steelmaking Efficiency

At the center of the steelmaking process are arc furnace electrodes, which act as conductors of electrical energy inside the furnace. These electrodes sustain arcs that reach over 3000°C, melting scrap metal and refining molten steel.

Rongsheng produces a complete range of EAF electrodes — Regular Power (RP), High Power (HP), and Ultra High Power (UHP) — all designed for specific furnace loads and operational demands.

Key features of Rongsheng’s arc furnace electrodes include:

-

High Conductivity: Ensures efficient current transfer and faster melting cycles.

-

Mechanical Strength: Withstands the mechanical stress from continuous electrode feeding and arc movement.

-

Oxidation Resistance: Reduces consumption and extends service life, improving recovery potential.

-

Dimensional Precision: CNC-machined for stable connections and consistent performance in furnace environments.

With more than 20 years of experience, Rongsheng supplies electrodes that combine cost efficiency with longevity — helping operators minimize electrode consumption and maximize recovery value.

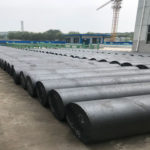

What Makes Rongsheng’s Graphite Electrodes for Sale Stand Out

Rongsheng’s graphite electrodes for sale are known globally for their reliable quality, technical precision, and adaptability to various furnace conditions. Whether customers operate small foundries or large industrial steel plants, the company offers electrode solutions tailored to specific melting capacities and power levels.

Distinct advantages of Rongsheng’s graphite electrodes include:

-

Superior Raw Materials

Produced using high-quality needle coke and refined coal pitch, the electrodes exhibit low ash content, high density, and excellent electrical performance. -

Advanced Manufacturing Technology

Through controlled baking, multiple impregnation stages, and graphitization at up to 3000°C, Rongsheng achieves structural uniformity and stable resistivity across every electrode. -

Comprehensive Product Range

-

RP electrodes for standard furnaces.

-

HP electrodes for high-power melting operations.

-

UHP electrodes for large-capacity EAFs requiring rapid melting and short cycle times.

-

-

Matched Nipples for Secure Connections

Electrodes and nipples are machined in matched pairs, minimizing joint resistance and ensuring current stability during operation. -

Bulk Supply and Global Service

Rongsheng provides graphite electrodes for sale in bulk quantities, offering cost-effective pricing, on-time delivery, and technical after-sales support for international clients.

Applications – Where Arc Furnace Electrodes Deliver Performance

Rongsheng’s products are used in diverse industrial fields where electrical conductivity and heat resistance are critical.

1. Electric Arc Furnace Steelmaking

In steel plants, arc furnace electrodes carry high currents to generate the intense heat needed to melt scrap and refine alloys. Rongsheng’s UHP electrodes ensure fast melting with lower power consumption and reduced electrode wear — improving both furnace productivity and electrode recovery rate.

2. Ladle Furnace Refining

In secondary refining operations, electrodes maintain the molten steel’s temperature and facilitate alloying reactions. Rongsheng’s HP electrodes deliver stable arcs that preserve energy and maintain metallurgical consistency.

3. Ferroalloy and Silicon Smelting

In submerged arc furnaces, electrodes must endure high contact resistance and chemical reactions with the furnace charge. Rongsheng’s RP and HP electrodes offer excellent thermal shock resistance and mechanical strength under continuous load.

4. Non-Ferrous and Chemical Industries

Beyond steelmaking, graphite electrodes are used for melting copper, nickel, and titanium, and for producing advanced materials like corundum and silicon carbide.

In each application, proper operation and recovery of electrodes can significantly extend product life and reduce production costs.

Optimizing Graphite Electrode Recovery – Rongsheng’s Recommendations

Rongsheng provides technical advice to customers on improving electrode recovery and utilization efficiency. Key recommendations include:

-

Monitor Current Density: Maintain optimal current per electrode diameter to prevent premature oxidation and breakage.

-

Control Furnace Atmosphere: Limit oxygen exposure during operation to reduce electrode oxidation.

-

Use Quality Nipples: Ensure precise nipple-thread fit to prevent joint loosening and energy loss.

-

Implement Butt Recovery Programs: Collect and recycle electrode stubs by crushing and reprocessing as carbon additives or secondary materials.

These measures not only enhance recovery but also improve furnace stability and long-term operational savings.

Customer Example – Combining Performance and Recovery

A steel plant in Southeast Asia partnered with Rongsheng to replace inconsistent third-party electrodes with Rongsheng’s HP arc furnace electrodes. After six months of operation, the results were significant:

-

Electrode consumption reduced by 14%.

-

Recovery rate of usable graphite butts increased by 20%.

-

Energy savings of 7% per ton of steel.

This case demonstrates how high-quality electrodes, when paired with recovery-focused practices, can transform furnace efficiency and profitability.

Why Choose Rongsheng

-

Integrated Production: From raw material preparation to machining and testing under one roof.

-

Technical Support: Guidance on electrode selection, recovery strategy, and EAF operation optimization.

-

Global Reach: Customers in more than 120 countries across steel, alloy, and chemical industries.

-

Sustainability Commitment: Promotes recycling and eco-friendly production to reduce industrial carbon footprints.

-

Proven Reliability: ISO and CE-certified graphite electrodes trusted by international steel producers.

Rongsheng’s focus on performance, recovery, and sustainability makes it one of the most reliable partners in the graphite electrode industry.

Conclusion

As industries pursue higher efficiency and lower emissions, graphite electrode recovery has become an integral part of sustainable steelmaking. By supplying durable and precise arc furnace electrodes, and offering graphite electrodes for sale that meet global standards, Rongsheng enables manufacturers to optimize both performance and resource utilization.

With its advanced production capabilities, commitment to quality, and expertise in recovery optimization, Rongsheng continues to lead the way in helping industries turn energy into innovation — responsibly and efficiently.

📩 Contact Rongsheng today for quotations or technical consultation.

🌐 Visit the website to explore available graphite electrodes for sale and learn more about electrode recovery solutions.