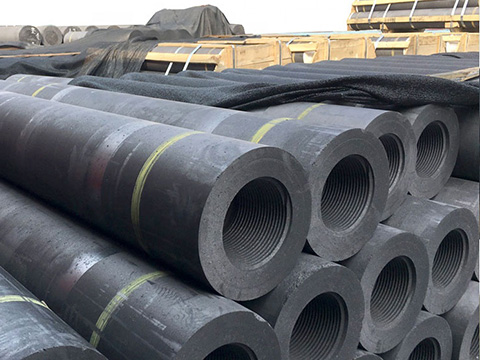

With the increasing complexity of die geometry and the diversification of product application, the discharge accuracy of spark machine is required more and more. Graphite electrode feature by easy machining, high removal rate of discharge machining and small graphite loss. Therefore, some customers of group based spark machine abandon copper electrode and use graphite electrode instead.

In addition, some specially shaped electrodes cannot be made from copper, but graphite is easier to shape, and the copper electrode is heavier, which is not suitable for processing large electrodes, all these factors lead to the use of graphite electrodes by some group based spark machine customers. In terms of processing speed, graphite electrode feature is easier to process, and the processing speed is obviously faster than copper electrode. For example, graphite is processed by milling process, which is 2 ~ 3 times faster than other metal processing and does not require additional manual processing, while copper electrode requires manual grinding.

In general, graphite has superior properties that copper cannot match:

1. Processing speed: high speed milling rough processing is 3 times faster than copper; High speed milling finishing is 5 times faster than copper;

2. Good processability, able to achieve complex geometric modeling;

3. Light weight, less than 1/4 of the density of copper, easy to clamp the electrode;

4. The number of single electrodes can be reduced, because composite electrodes can be made by binding;

5. Good thermal stability, no deformation and no burrs.

If the milling time of graphite electrode is compared with that of copper electrode, the milling time of graphite electrode is 67% faster than that of copper electrode. As a result, the processing time is greatly reduced, which also reduces the manufacturing cost. The design of graphite electrode is different from that of traditional copper electrode. Many mold factories typically have different reserves for rough and finish machining of copper electrodes, while graphite electrodes use nearly the same reserves, which reduces the number of CAD/CAM and machine machining. This alone is sufficient to greatly improve the precision of mold cavities.

Under normal circumstances, the graphite electrode feature remarkable. The machining speed of graphite can be 2~5 times faster than that of copper, and the material is less prone to deformation. The advantages are more obvious in the processing of thin bar electrodes. The softening point of copper is about 1000℃, which is very easy to produce deformation due to heat, while the sublimation temperature of graphite is 3650℃, and the thermal expansion coefficient is only 1/30 of that of copper. We are a manufacturer of high quality graphite products.